Best Patch For Osb Floor

Osb is in great shape but there is a tiny bit of mildew on the surface in a few spots and some small gouges where the gyp crete took up a quarter sized strand.

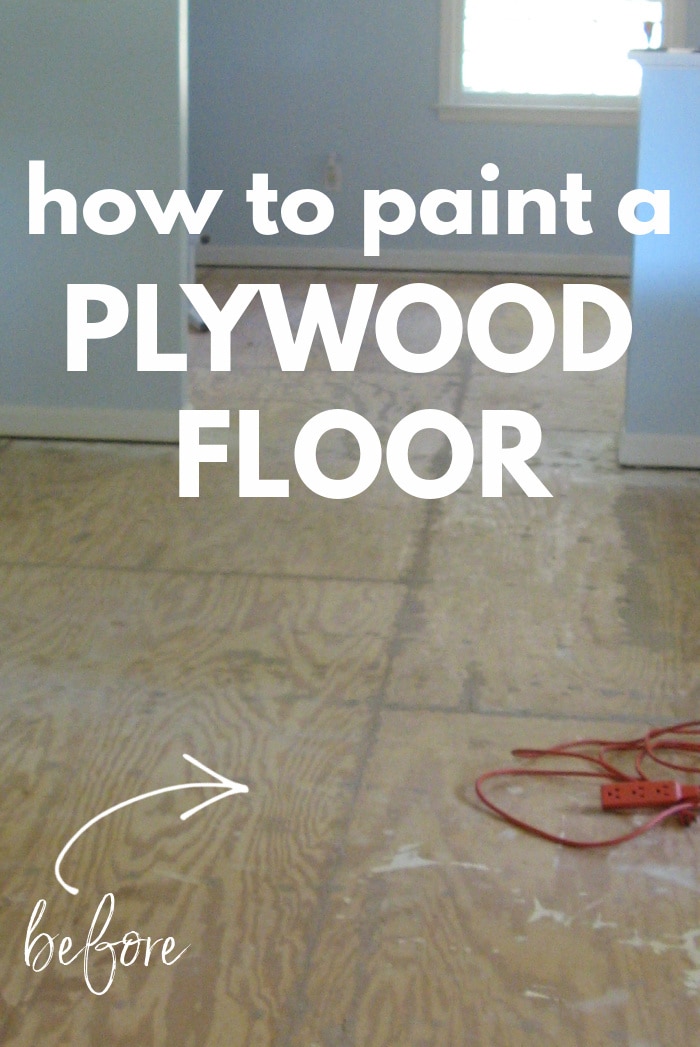

Best patch for osb floor. When a roofless partially built structure takes on water the plywood or osb used for floor decking can absorb water swell delaminate and require sanding or replacement before finish flooring. Osb and plywood are both commonly sold in 4 by 8 foot sheets but osb can be made in much larger panels up to 8 by 24 feet. Osb is not attractive enough to serve as a floor covering not only is the chip board appearance unattractive but the surface is also often marked with grid lines and manufacturer markings. Will either go with hardiebacker 500 or self leveling concrete to raise floor up to height to tile.

Using larger osb panels can be an advantage when flooring a big or odd size shed reducing the number of joints in a floor. Cement based formulations such as henry 555 levelpro are designed for wood and concrete subfloors while patching compounds such as fix it all are composed primarily of calcium carbonate and silica quartz and are intended primarily for wood. What to use for filler before laying vinyl flooring. Osb oriented strand board.

Leveling compound comes in two basic formulations. The two types of subfloor material oriented strand board osb and plywood are both constructed of wood fibers combined with glue and pressed into durable panels that are more than adequate for. Osb when exposed to the weather will eventually swell and bubble up minor instances of bubbling can be sanded but for the most part the osb is irreparable and should be replaced. A plywood subfloor generally uses 1 2 inch to 3 4 inch thick sheets of plywood that have one rough side which faces down and one smooth side which faces up.