Best High Temp Ceramic Cement

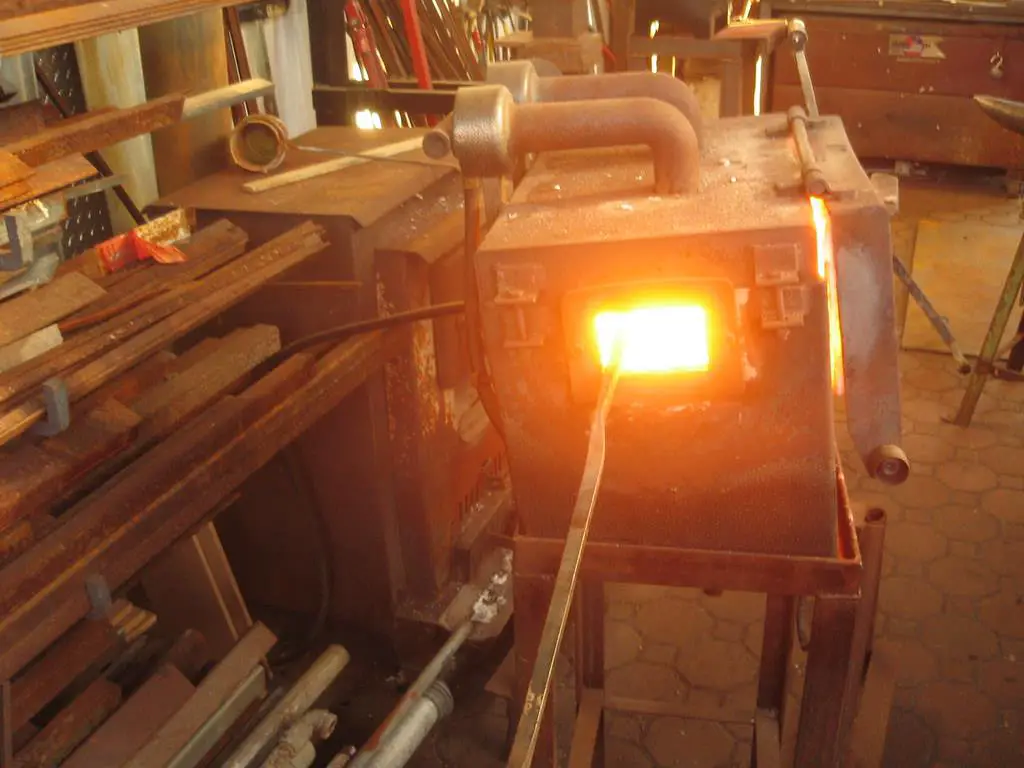

High temperature refractory cement also called aluminate cement adopts bauxite and limestone as the main raw materials through firing to get clinker with 50 alumina content and main component of calcium aluminate and then grind the clinker to be hydraulic cementing materials its refractoriness is not less than 1580.

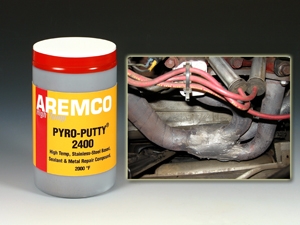

Best high temp ceramic cement. What degree of thermal conductivity is needed. This refractory mortar is designed to successfully withstand high sulphur fuel reducing atmospheres carbon deposition erosion and abrasion. The right ceramic cement electrical manufacturer s trial order kit hydraulic sets. Loucast 3000 degree castable refractory is a dense castable refractory mortar rated for 3000 f it is low iron content with high purity.

Thermal considerations what is the maximum temperature that the cement must withstand. High temperature cement refractory can be used to make refractory mortar. Sakrete high heat mortar is a dry medium duty mortar ideal for setting masonry units in fireplaces fire pits or chimney applications such as setting. Some manufacturers may produce their products in the tiny workshop.

It is not unusual to blend. They can hardly stand up to drops gets knocked down and fall overs. A ceramic material is an inorganic non metallic often crystalline oxide nitride or carbide material. It is possible to be cheated in the purchasing of refractory cement.

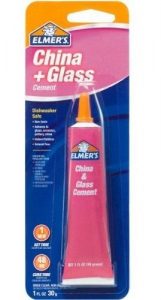

Our line of high temperature performance cements is used for bonding ceramic metal and glass in the electrical mechanical met. High temperature fibrous ceramic materials legendary heritage in cost effective high performance materials see our products high temperature fibrous. In this section of the blog post we will go through and quickly compare our top five picks for the best glue for ceramic. Some elements such as carbon or silicon may be considered ceramics wikipedia.

However it s difficult to remove cured cement. The harms of fake high temperature refractory cement. These products are best suited for thin film bonding and coating appli cations from 2 to 125 mils. A ceramic has been described thus.

As good looking as they are ceramic dinnerware tiles sinks etc. Best glue for ceramic. These properties are then matched to the appropriate cement. Solvent 10 sodium hydroxide.