Benefits Of Ceramic Exhaust Header Coating

One of the reasons why you would want to buy the vht paint would be because it ensures a long lifespan of the header.

Benefits of ceramic exhaust header coating. Coatings may dull in appearance over time. Exhaust manifold ceramic coating cost. Increase performance reducing the backpressure. While the coating is durable the part will have to be sent back to them for repair if you chip it.

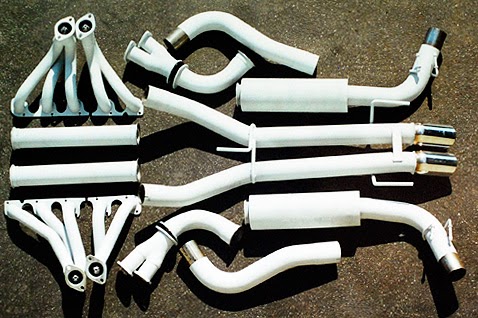

Ceramic coatings help increase the speed and maintain the quality of exhaust gas flow. Coating your extractors headers or manifolds with hpc s fully australian made ceramic exhaust coatings will not only make them look fantastic and help them last longer the under hood heat reduction and performance gains that you will see will be significant. Inside the exhaust tubes. High quality ceramic coated exhaust parts are more expensive.

You will have to spend a lot less on your headers or exhaust pipes thanks to this paint. Benefits of ceramic coating your exhaust manifold. Looks great some coatings resemble chrome plating. Ceramic coatings can help improve the performance of your headers turbo parts and exhaust pipes.

Even if you are already using a high grade stainless steel or titanium set. Ceramic coating also sometimes called nano ceramic coating is a permanent or semi permanent solution to your worries depending upon the coating and type of polymer used. Due to its chemically intrinsic properties it does not break down in normal atmospheric conditions like rain or summer. Manufacturers use a special process to apply the coating.

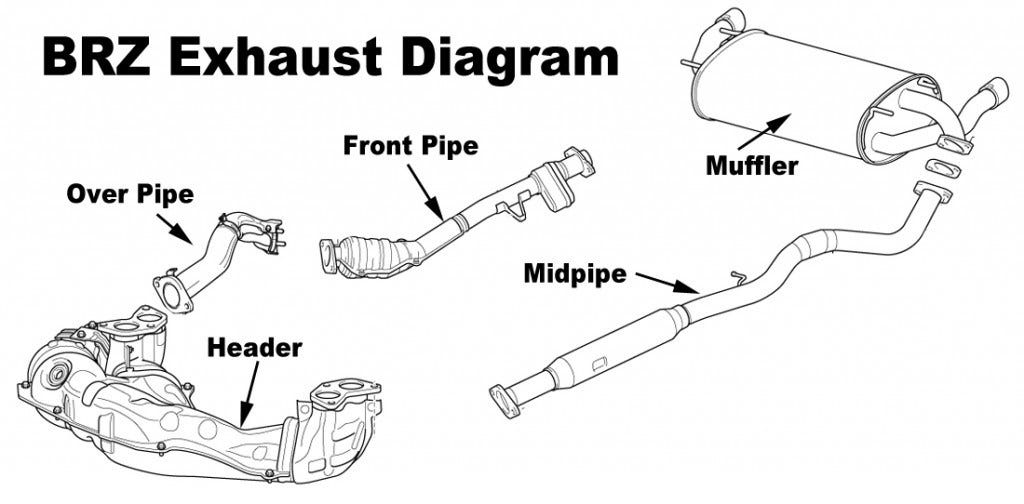

It lasts longer as the coating does not allow rust to collect on the surface. Uncoated exhaust headers rust more easily than exhaust systems coated with a high heat resistant ceramic coating. Thanks to the ceramic and silicon finishing. While there is nothing stopping you from getting the full exhaust stystem coated we have to state that the effect diminishes the further back you go and the main point of this exercise is to lower the engine bay temperatures.

In other words ceramic coated headers look and function the same on mile one as they do on mile 300 000. A ceramic coated header will reduce the heat in the engine bay and direct heat through the exhaust pipes which means greater engine efficiency. Ceramic has high resistance and is very durable. Ceramic coatings protect the exhaust system from corrosion in two ways.

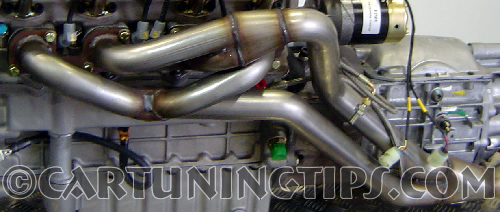

Using high temperature ceramic coating on the headers keeps the heat where you want it. Exhaust coatings provide thermal oxidation protection meaning your exhaust systems are less likely to develop rust or corrosion. A ceramic header coating also provides protection against the corrosive materials in the exhaust. Jba ceramic coated headers.

Ceramic coatings can increase performance. Due to the cost involved we generally see the main exhaust headers upto the catalyst treated with a ceramic coating.