Benefits Ceramic Coating Intake Manifold

We also offer thermal dispersant coatings that will act as a radiator or intercooler which helps remove heat from the parts its applied to.

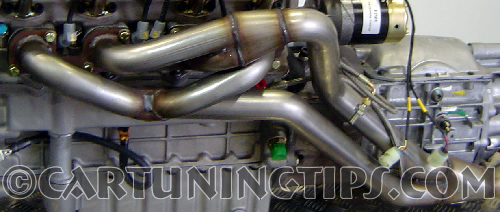

Benefits ceramic coating intake manifold. A ceramic header coating also provides protection against the corrosive materials in the exhaust. We often get asked what are the benefits of high temperature ceramic coating for intake manifolds headers and other parts of the exhaust system that generate excessive heat. Ceramic coating also sometimes called nano ceramic coating is a permanent or semi permanent solution to your worries depending upon the coating and type of polymer used. The ceramic coating will obviously insulate the manifold but will also smooth out the rough casting of the aluminum.

Whether it is for performance or show coating an exhaust manifold is valuable to you. In this instance you are dealing with heat that is generated by the engine. We can apply this coating to intake manifolds or any part you want to stay cool. The manifold will live longer as well as look nicer.

Ceramic coating a pair of full length four tube headers in any color starts at 215 and shorty type headers and cast iron exhaust manifolds start at 125 per pair or 65 each. My thought was if i can reduce the radiant heat entering the manifold it should reduce my intake temps further. Let s discuss performance first. There is now an alternative to ceramic coatings with the arrival of ceramic wraps on the market which can be cut and wrapped around the exhaust.

We charge 145. Cast iron manifolds are more prone to this but we have to ask what a cast iron manifold is doing on a performance engine as stainless steel headers flow much more freely. Ceramic coating can be applied to any exhaust piping turbochargers housings and much more. 2 the coating is a thermal barrier thus keeping heat within the manifold or header.

Coating an intake manifold v8 v6. There are two reasons for coating an intake manifold. You will also acquire heat from the hot oil that may be tossed up under the underside of. The first would be performance the second appearance.

Coating your headers in ceramic improves their heat resistance and keeps them from being tarnished or damaged by the heat. There are a number of benefits for this. I run a killer chiller and on a dyno average an ita2 temp of 88 f.